SEE OUR SERVICE DETAILS.

From knowledge management to innovation

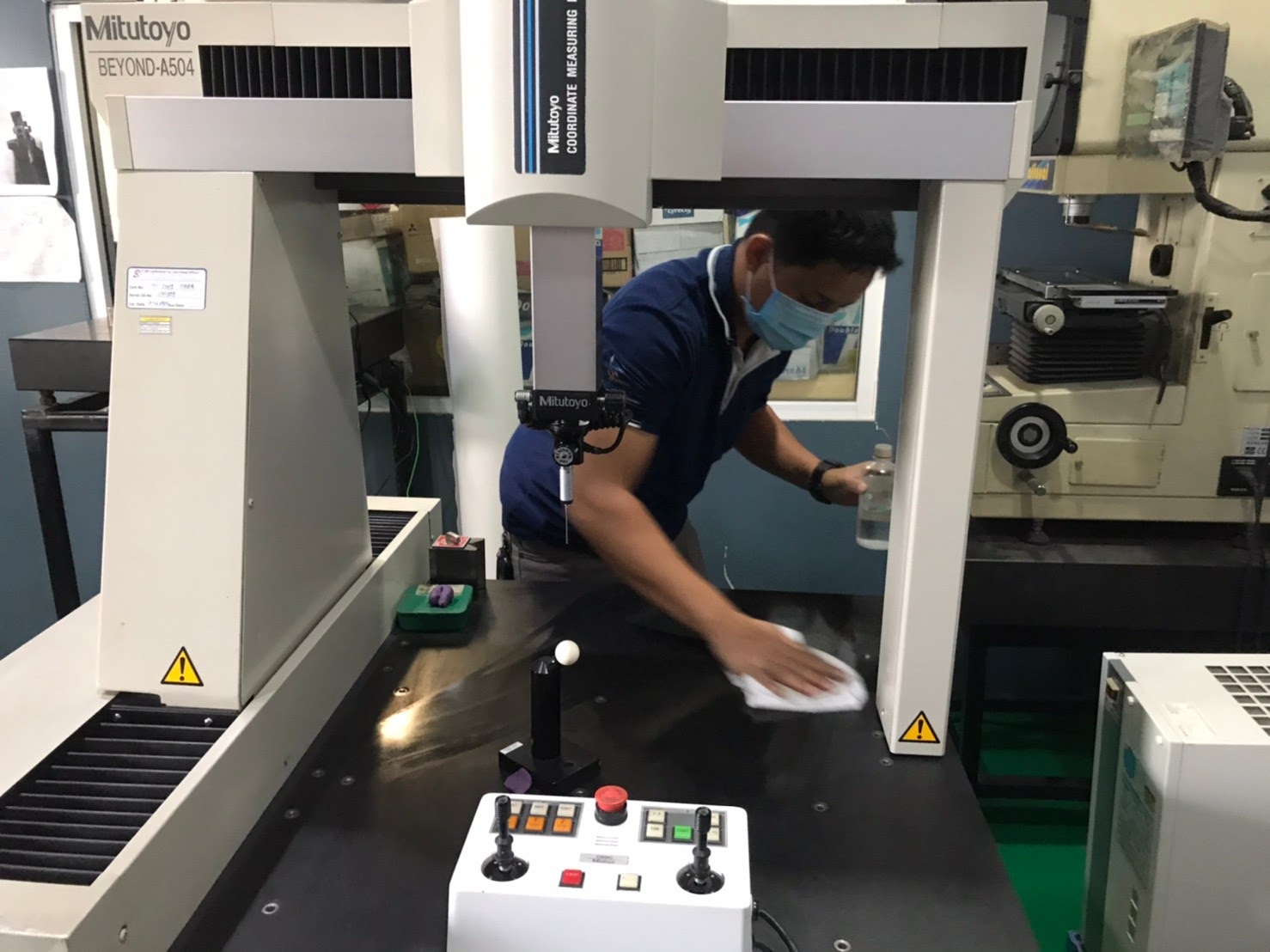

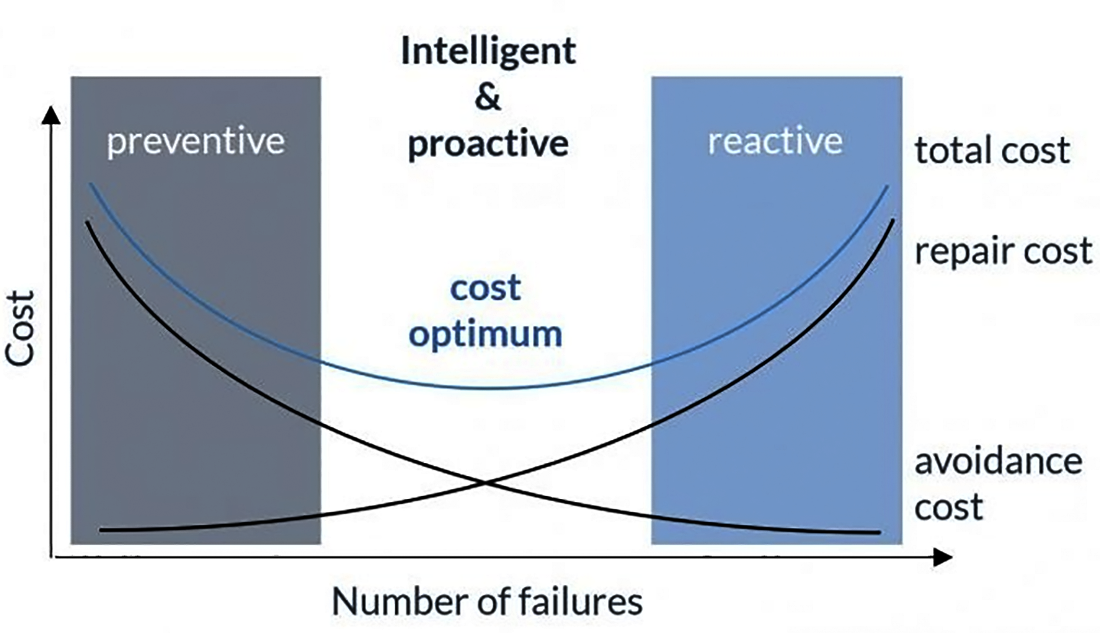

Long-term use of equipment, tools, machines is subject to wear and tear, posing a risk of breakdown and loss, which, if left to occur, affects work processes, product manufacturing, quality control or even Personnel safety If preventive maintenance procedures are adopted Will enable the company to predict that When will the company have to repair the machines before they are damaged? Including the removal of unnecessary parts that affect the waste of the machine. In addition, it can increase the service life of the machine. By using the results obtained from preventive maintenance This process allows the company to reduce the risks in the manufacturing process. Reduce time spent on maintenance Control the cost of maintenance. Develop the image of the organization Reduce material hoarding costs by planning future purchases. For this reason, we have to maintain the equipment. Those tools will be continuously available for use. This will reduce the risk of unexpected events. And also extending the service life and increasing the stability of the sustainable operation Observation of preventive maintenance

Comparison chart for repair and maintenance work prices

MACHINE CARE AND MAINTENANCE THE STEPS ARE AS FOLLOWS.

Our preventive maintenance programs are designed to minimize tool damage and avoid system failures. This is done by finding and repairing problems in the early stages, thereby reducing overall repair costs, PM services tailored to the needs of each end-user. We keep a history record of each unit that is accessible through our computer tracking system, after each PM it is reported to the end user. This report includes any device problems or required repairs.

maintenance plan

BP Calibration offers an Annual Service Contact service to help plan maintenance throughout the year of your machinery.

MAINTENANCE OPERATION

All of our repaired parts are backed by 3 months service, 6 months shelf warranty, on our promise of quality and value.

MAINTENANCE STRATEGY

We can replace the repaired parts for you in 7-10 days normally, but if urgent we will expedite your order within 48 hours.

EN

EN  TH

TH