Selling stylus for Faro arms.

A FULL RANGE OF STYLI FOR ALL APPLICATIONS

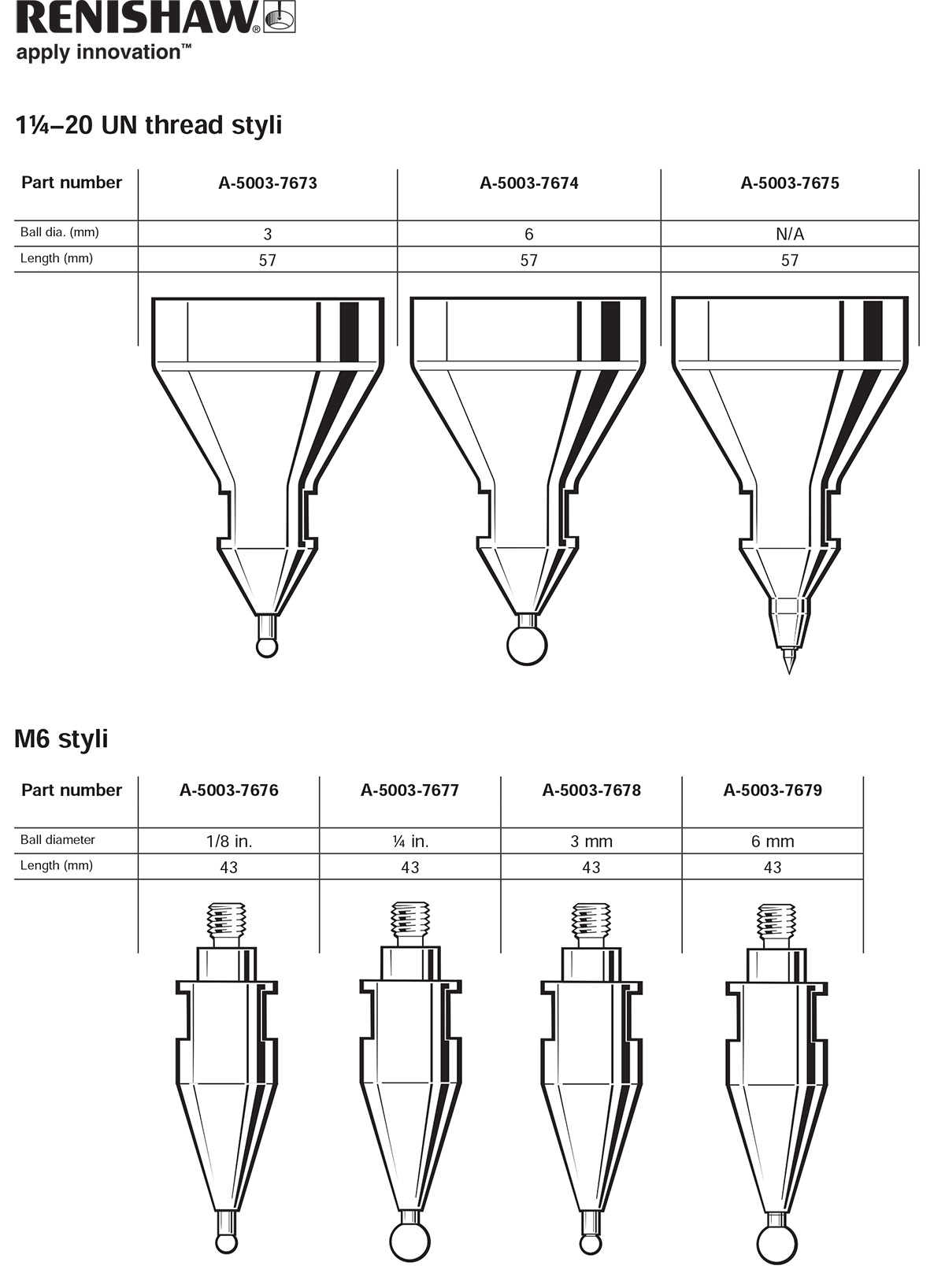

| Renishaw part number | Faro part number | Description |

|---|---|---|

| A-5003-7673 | 12453 | 3 mm zirconia ball probe |

|

A-5003-7674 |

12454 | 6 mm zirconia ball probe |

| A-5003-7675 | Probe0071 | Point probe |

| A-5003-7676 | Probe0066 | 1/8" zirconia ball probe with M6 thread |

| A-5003-7677 | Probe0068 | 1/4" zirconia ball probe |

| A-5003-7678 | Probe0065 | 3 mm zirconia ball probe with M6 thread |

| A-5003-7679 | Probe0067 | 6 mm zirconia ball probe with M6 thread |